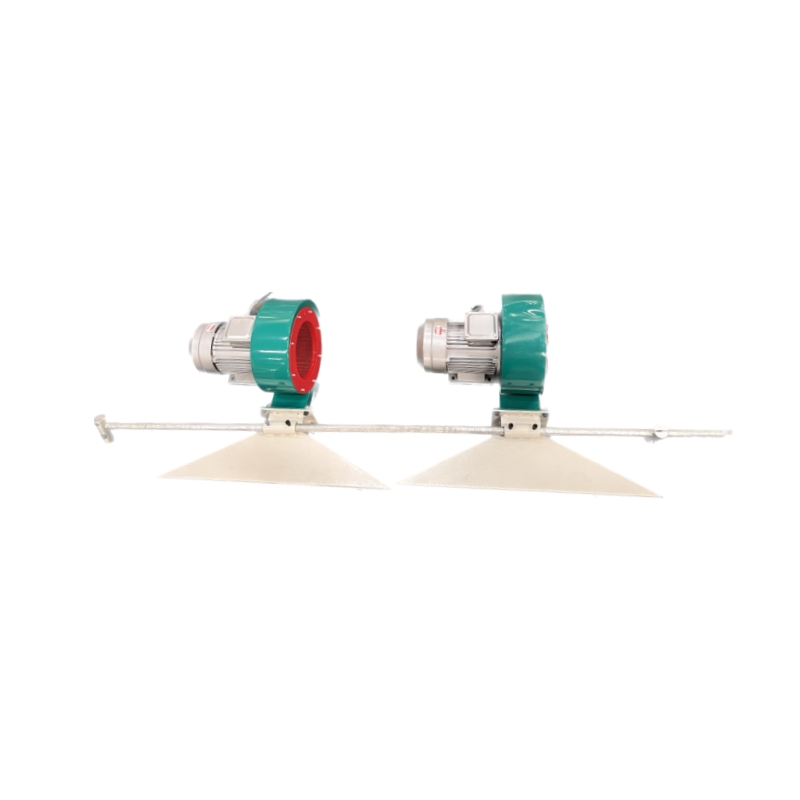

a. Dust cleaning part

2 rollers have simple brush dust cleaning machine,3 rollers have double sides dust cleaning machine.

b. Glue coating part

both of them are controlled by seperated motor,2 rolles pur laminating machine includes silicon roller and steel roller,but 3 rollers pur laminating machine have silicon,steel and ceramic roller,ceramic roll for shaving glue on the panel,suitable for high glossy pvc.

c. Pressing part

3 rollers pur laminating machine controlled by seperated motor,2 rollers controlled by shared motor,so 3 rollers is more stable than 2 rollers,especially suitable for high glossy pvc.diameter of 3 rollers is 320mm,2 rollers is 240mm,3 rollers give a bigger pressure and smoother flat.

d. Application

3 rollers pur laminating machine suitable for thin high glossy PVC/PET+smooth panel

2 rollers pur laminating machine suitable for matte PVC+rough surface panel