Meta Description: Discover industrial-grade slitting machines for PVC, PET, and paper

materials (15-1300mm cutting width). Boost efficiency in packaging, laminating (PUR/paper),

and wrapping workflows. Free consultation for tailored solutions.

Introduction to Industrial Slitting Machines

In today’s fast-paced manufacturing landscape, precision and versatility are non-negotiable. Slitting machines have emerged as indispensable tools for industries ranging from packaging to laminating, offering unmatched efficiency in material processing. Designed to seamlessly integrate with wrapping machines, PUR laminating machines, and paper laminating machines, our slitting systems deliver high-speed, accurate cuts for PVC, PET, and paper materials. This guide explores how a 15-1300mm slitter can revolutionize your production line while optimizing costs and quality.

Why Slitting Machines Are Essential for Modern Production

Multi-Material Compatibility

PVC & PET Films: Ideal for food packaging, shrink wraps, and industrial laminates.

Paper Rolls: Perfect for labels, cardboard, and eco-friendly packaging solutions.

Hybrid Materials: Compatible with laminated sheets from PUR/paper laminating machines.

Precision Cutting for Seamless Integration

Achieve consistent widths (15-1300mm) to match downstream equipment like profile wrapping machines or edge banding systems.

Minimize material waste with laser-guided alignment and programmable controls.

Enhanced Productivity

Process 10-30% faster than manual cutting methods.

Key Features of Our Slitting Machines

Adjustable Cutting Range

Handle ultra-narrow 15mm strips for delicate labels or 1300mm-wide rolls for profile wrapping and flat laminating .

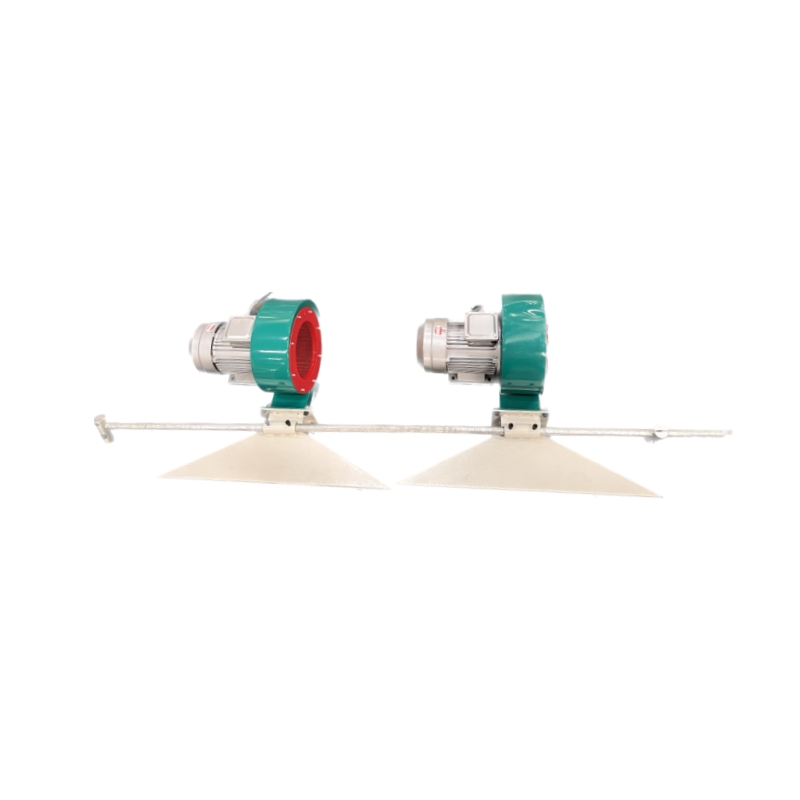

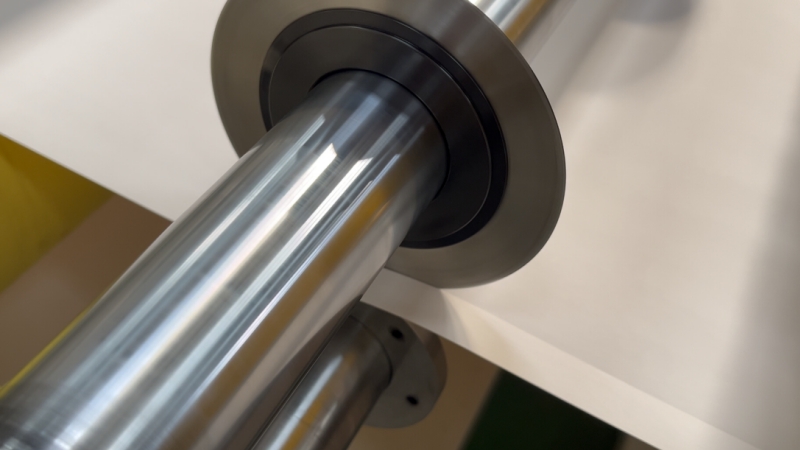

Industrial-Grade Components

Tungsten carbide blades for long-lasting sharpness.

Universal Compatibility

Sync with paper laminating machines for post-lamination trimming.

Feed directly into profile wrapping machines for edge protection or decorative finishes.

Applications Across Industries

1. Wrapping Solutions

Food & Pharma: Cut PVC/PET films for sterile wrapping.

E-commerce: Slit paper rolls into custom-sized void-fill sheets.

Retail: Produce uniform gift wraps or adhesive labels.

2. Laminating Workflows

Trim edges of paper-PUR laminates for furniture or automotive interiors.

Convert laminated boards into precise widths for construction panels.

3. Wrapping Machine Integration

Prep materials for profile wrapping machines used in window/door frame coatings.

Technical Specifications

ParameterDetails

Cutting Width15mm–1300mm (adjustable in 1mm increments)

Material Thickness0.02mm–3mm

Max Speed150m/min

Power5kW–15kW (customizable)

CompatibilityWrapping machines, PUR/paper laminators

Reduce material waste by 18% with precision slitting.

Lower labor costs through automation.

Scalability

Easily adapt to new materials (e.g., biodegradable films) or widths.

Sustainability

Support eco-friendly practices with paper recycling compatibility.

Why Partner With Us?

20+ Years of Expertise: Trusted by 500+ global manufacturers.

Custom Solutions: Tailor machines to your wrapping/laminating setup.

After-Sales Support: Spare parts, blade sharpening, and IoT monitoring.

🌐 Visit: HESSAN WEBSITE

🔗 Explore Related Equipment: