Introduction to PUR Flat Lamination Technology

PUR (Polyurethane Reactive) flat lamination lines have revolutionized the manufacturing industry by offering superior bonding solutions for panel production. Unlike traditional methods, PUR technology ensures stronger adhesion, moisture resistance, and compatibility with diverse materials. For businesses considering this investment, the critical question is:

How quickly can a PUR lamination line pay for itself?

In this guide, we analyze Hessan’s PUR flat lamination line, its capabilities, and the factors influencing ROI.

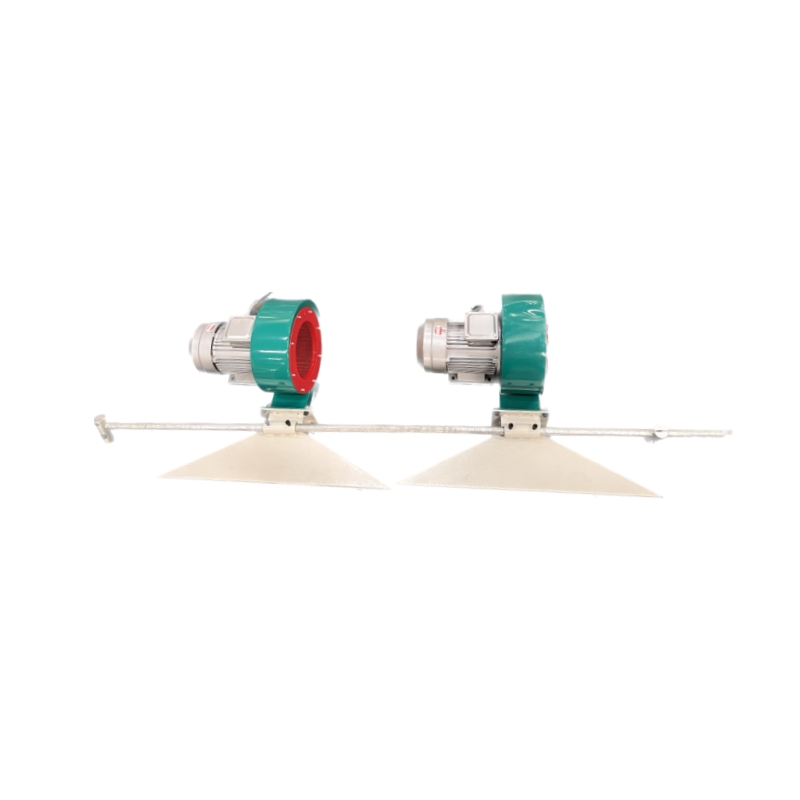

Key Specifications of Hessan’s PUR Flat Lamination Line

Compact Design for Flexibility

Dimensions: 10m (L) × 3.5m (W)

Space-saving footprint ideal for small to mid-sized factories.

Easy relocation due to modular construction.

Industrial-Grade Durability

Frame: 40mm-thick aluminum alloy.

Lifespan: 20+ years with minimal maintenance.

Built to withstand high-volume production cycles.

High-Speed Production

Capacity: 4–6 boards per minute.

Daily Output: 2,000+ 4×8ft sheets (single shift).

Reduces bottlenecks in large-scale orders.

Material Versatility

Compatible with aluminum, veneer, acrylic, PVC, high-gloss PETG, and more.

Eliminates the need for multiple machines for different materials.

Calculating ROI: Factors to Consider

1. Initial Investment vs. Long-Term Savings

Machine Cost: Average PUR lamination lines range from 150,000 to 300,000. Hessan’s model balances affordability and advanced features.

Labor Savings: Automated operation reduces manual labor by 50–70%.

Material Efficiency: Precision application cuts adhesive waste by 15–20%.

2. Production Volume and Profit Margins

Example: A factory producing 2,000 boards/day at 10prfit/boardearns20,000 daily.

At 80% utilization, the machine pays for itself in 15–30 days (depending on model).

3. Reduced Downtime and Maintenance

Aluminum alloy frame resists corrosion and wear.

Annual maintenance costs: <2% of machine price.

Case Study: ROI in Real-World Scenarios

Furniture Manufacturer in Canada

Challenge: Needed to laminate 1,500 MDF boards/day for kitchen cabinets.

Solution: Installed Hessan’s PUR line.

Results:

ROI Achieved: 22 days (due to 24/7 shifts).

Defect rate dropped from 5% to 0.8%.

Signage Company in the Egypt

Challenge: Inconsistent bonding of acrylic sheets.

Solution: Upgraded to Hessan’s multi-material compatible line.

Results:

ROI Achieved: 40 days (part-time operation).

Expanded product range to include luxury PETG finishes.

Why Hessan’s Machine Stands Out for Fast ROI

Speed-to-Profit Ratio

Processes 30% faster than hydraulic laminators.

Eliminates curing time with instant bonding.

Energy Efficiency

Consumes 25% less power than older models.

Smart sensors optimize adhesive usage.

Future-Proof Design

Upgradable software for new material profiles.

Compatible with Industry 4.0 automation systems.

Common Concerns Addressed

1. Is PUR Lamination Suitable for Small Businesses?

Yes! Compact size and scalable output make it ideal for startups.

Leasing/financing options available.

2. How Complex Is Operation?

Intuitive touchscreen controls.

Training provided (2–3 days for technicians).

3. Environmental Impact

Low-VOC adhesives meet EU REACH standards.

Recyclable aluminum frame reduces landfill waste.

Step-by-Step Guide to Maximizing ROI

Audit Your Production Needs

Calculate current labor/material costs.

Identify high-demand products for prioritization.

Run a Trial Batch

Test multiple materials to gauge efficiency.

Compare defect rates pre/post-installation.

Optimize Shifts

Run 2–3 shifts to accelerate payback period.

Use downtime for maintenance.

Market New Capabilities

Promote “luxury finishes” (e.g., high-gloss PETG) to premium clients.

Offer faster turnaround times to secure contracts.

Conclusion: Is a PUR Lamination Line Worth the Investment?

For manufacturers prioritizing speed, versatility, and long-term savings, Hessan’s PUR flat lamination line offers a compelling ROI. With payback periods as short as 3–6 weeks in high-volume scenarios, it’s a strategic upgrade for staying competitive. By reducing waste, expanding product ranges, and slashing labor costs, this technology transforms production lines into profit centers.

Ready to Calculate Your Custom ROI?

Contact Hessan’s team for a free cost-benefit analysis tailored to your production volume.