Discover how Hessan delivers industrial-grade PUR lamination lines to Morocco with precision. Explore the technical advantages of our flat laminating machines and client appreciation initiatives.

1. A Milestone Moment: 3 Containers of PUR Laminating Machines Set Sail to Morocco

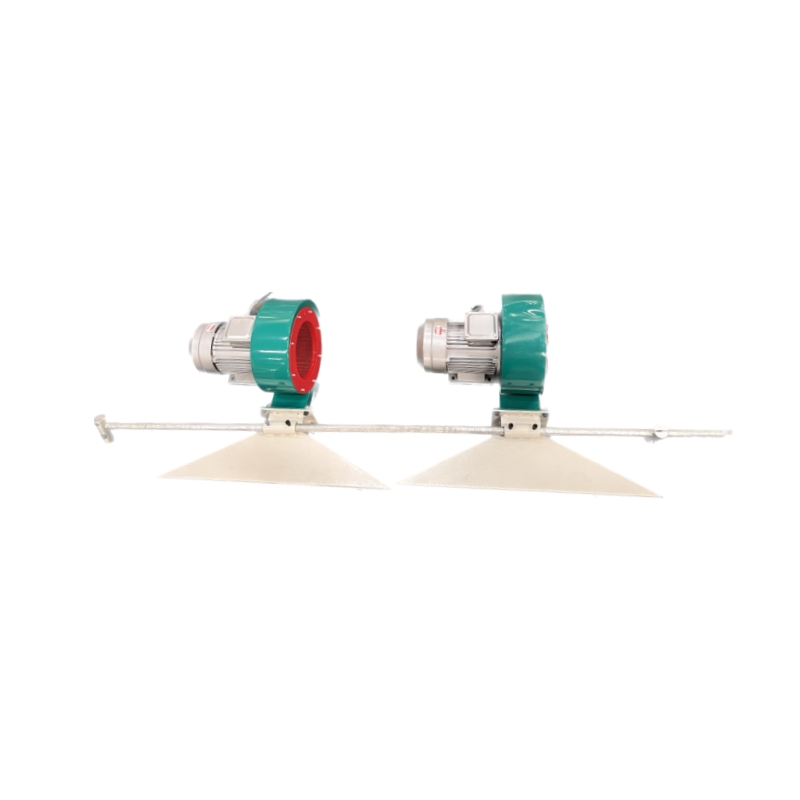

Today, we proudly loaded HY-PUR-1400D full automatic laminating machines into 40HQ containers, destined for our client’s factory in Meknes. This marks our successful delivery in North Africa in 2025. Your trust continues to showcase the brilliance of Chinese intelligent manufacturing across the Mediterranean!

2. Laminating Solutions Tailored for Africa

The PUR lamination line delivered this time includes the following innovations:

✅ Smart Temperature Control: Adapts to Moroccan workshop environments (15–45°C)

✅ Multi-Layer Composite Technology: Precision handling of substrates (MDF/metal/acrylic) from 0.3–40mm thickness

✅ Energy-Saving Core: 38% less PUR adhesive consumption compared to traditional laminating machines

3. Strict Shipping Standards Ensure Safety

We implemented a "Dual Protection" shipping plan:

🔹 7-Layer Protective Packaging

Nano moisture barrier film (humidity <20%)

Shock-absorbing honeycomb structure (impact resistance >10G)

🔹 Smart Logistics System

Laser-guided modular loading (96% container space utilization)

Cloud-monitored temperature, humidity, tilt, and vibration data

4. Client Success Story

Feedback from Rabat Furniture Manufacturer Ahmed Group:

27% increase in production efficiency (compared to Italian equipment)

5. Certifications & Sustainability Commitment

International Certifications: CE, ISO 9001, Morocco COC

Eco-Friendly Upgrades:

◼ Recyclable packaging materials

◼ Energy-saving mode reduces power consumption by 25%

◼ ROHS-compliant components

6. Exclusive Client Appreciation Benefits

To thank our Moroccan clients, they will receive:

▷ Free Tropical Climate Maintenance Guide (English/French/Arabic)

▷ Priority VIP invitations to the 2025 CIFM/INTERZUM

▷ Extended 1-year warranty on core components