Discussion of protective measures

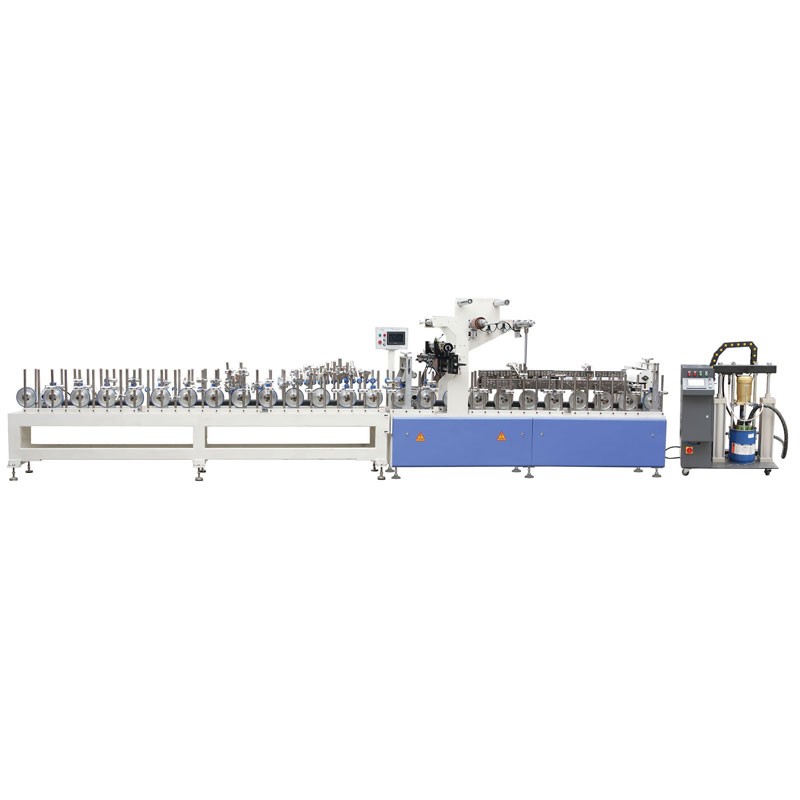

for applying PVC using a flat laminating machine:

the choice between protective film and pearl cotton

In the modern manufacturing and decorating industry, PVC (polyvinyl chloride) is widely used for flooring,

wall coverings and a variety of finishes due to its excellent durability and economy. And in the process of

laminating PVC materials to different substrates, the use of a flat laminator is an efficient option. However,

in this process, how to effectively protect the surface quality and bonding effect of PVC has become an

important issue. This article will discuss the use of protective film and the need for pearl cotton and its

application of the scene, to help industry practitioners to make a more informed choice.

First, the characteristics of PVC materials

PVC is a synthetic material with good physical properties, with excellent moisture resistance, corrosion

resistance and easy to clean. However, the surface of PVC is relatively soft and easily scratched or contaminated.

During the lamination process, any minor scratches or dirt may affect the final result. Therefore, it is particularly

important to choose the right protection when laminating with a flat laminating machine.

Second, the role of the protective film

1. Anti-scratch and abrasion

Protective film is usually made of polyethylene (PE) or polypropylene (PP) and other materials, with good transparency and toughness. In the lamination process, the protective film can effectively prevent tools or other materials on the surface of the PVC scratches. For high gloss PVC materials, the protective film is more able to maintain its bright appearance.

2. Dust and pollution prevention

On the construction site, dust and dirt are inevitable. Protective film can effectively isolate the external environment and prevent these pollutants from adhering to the PVC surface. Especially during the construction period, the existence of protective film can greatly reduce the difficulty of subsequent cleaning work.

3. Easy to remove

Protective films are usually designed with post-construction convenience in mind. Most films can be easily removed after application without leaving adhesive residue or damaging the surface of the PVC. This is an important advantage for projects that want to keep the material intact.

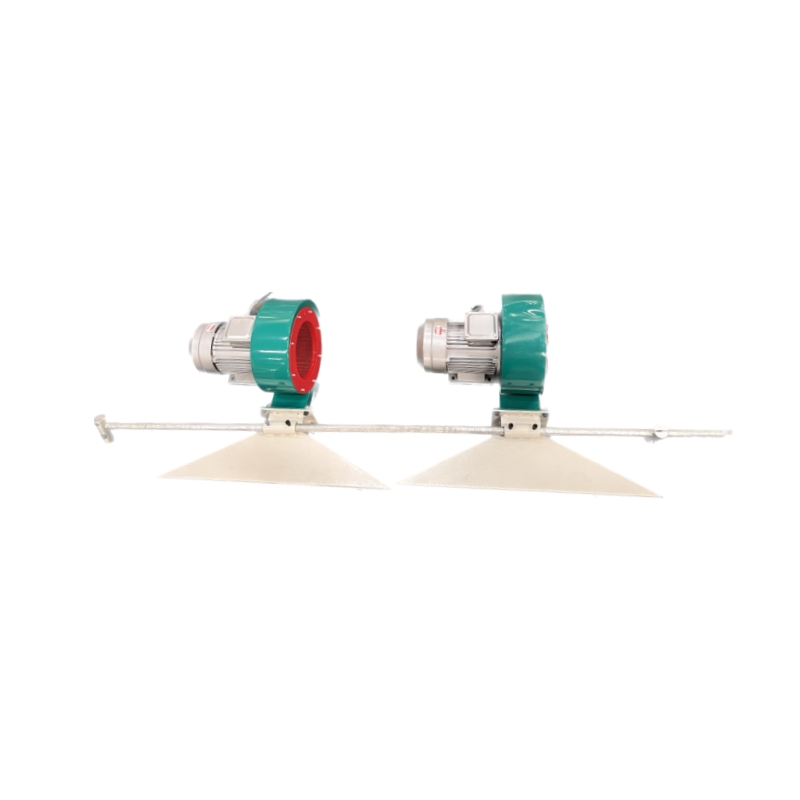

Third, the role of pearl cotton

1. Cushioning protection

Pearl cotton is a lightweight foam material commonly used to package and protect items. Its superior cushioning

properties can effectively absorb external impacts and protect the integrity of PVC during transportation

and handling. If PVC needs to be moved or handled frequently in the construction environment, laying

pearl cotton can effectively reduce the risk of accidental damage.

2. Moisture resistance

Pearl cotton has certain moisture-proof properties that can provide protection in humid environments. For

PVC materials that need to be used in wet spaces, especially in places such as bathrooms or kitchens, the

use of pearl cotton can help prevent moisture damage to the material.

3. Cost effectiveness

In some cases, pearl wool is relatively low cost and readily available for high volume construction or temporary

protection needs. This makes pearl cotton a cost-effective option, especially in projects with limited budgets.

Fourth, the choice of considerations

There are several factors to consider when deciding whether to use protective film or pearl cotton:

1. Project needs

The specific needs of the project are the primary consideration in choosing protection. If the project

requires very high surface quality, protective film may be a better choice; if the project involves

frequent handling or transportation, pearl cotton is more appropriate.

2. Environmental factors

Characteristics of the construction environment may also influence the choice. For example, in

wet environments, the moisture resistance of pearl wool may be advantageous, while in dry

and dusty environments, protective film may provide better protection.

3. Cost and budget

Budget constraints are also an important consideration. While protective film and pearl cotton

each have their advantages, in some cases it may be more pragmatic to use the lower cost material.

General Recommendations

In practice, many professionals choose to use a combination of protective film and pearl cotton to

fully utilize the advantages of each. For example, before laminating PVC, the first protective film to

protect the surface; in the construction and transportation process, and then use pearl cotton for

cushioning protection. This combination provides comprehensive protection at different stages and

ensures that the PVC material remains in optimum condition throughout its life cycle.

Conclusion

When applying PVC with a flat laminating machine, protective film and pearl cotton each have their

own unique advantages and application scenarios. Understanding their characteristics and functions,

combined with the actual needs of the project, can effectively improve the construction efficiency and

final results. Regardless of the choice of protection measures, the key is to ensure the integrity and

beauty of the PVC material, and ultimately achieve high-quality construction results. Choosing the

right protection will bring you higher efficiency and better quality of the finished product.