Wood laminating machine (Wood laminating machine) is a machine specialized in covering the surface of wood with a film. It allows a layer of film (usually PVC or PET film) to be applied to the surface of wood to increase its protection, aesthetics and durability.

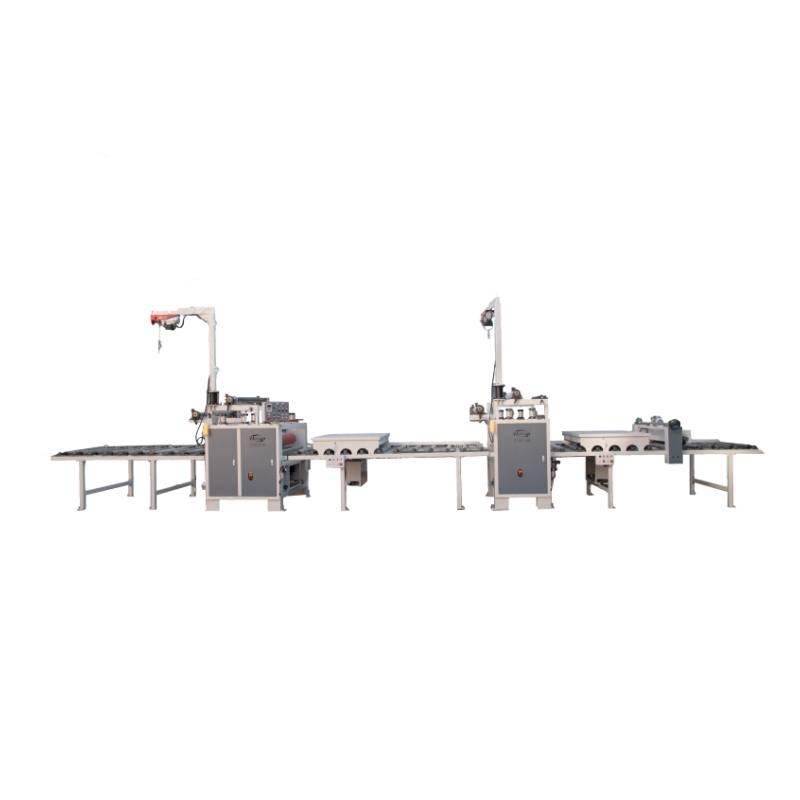

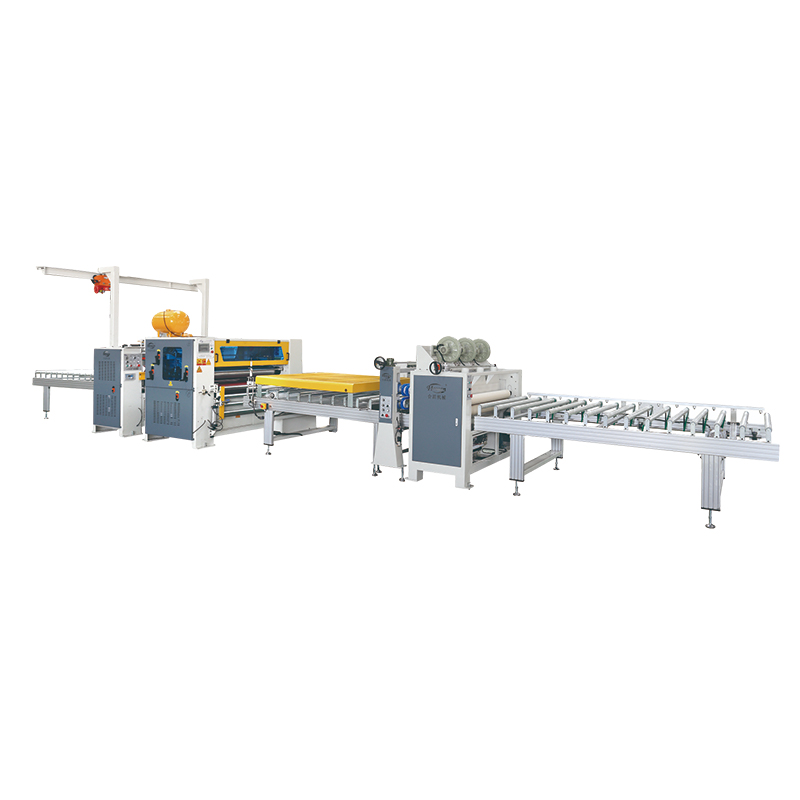

A wood laminating machine usually consists of the following main components:

Feed system: used to feed the wood into the machine for processing. This can be an infeed conveyor or roller system.

Film gluing system: Used to apply glue to the film in order to bond the film to the wood. This is usually a glue roller or spray system.

Pressing system: Used to press the film to the wood to ensure good adhesion. This can be a pair of press rollers or a platen system.

Heating System: Used to heat the film and wood to facilitate the bonding process. This is usually accomplished with heated rollers or hot plates.

Outfeed System: Used to remove the treated wood from the machine. This can be an outfeed conveyor or roller system.

A wood laminating machine can be used to make furniture, doors, windows, flooring, cabinets and other wooden products. It provides an extra layer of protection against moisture, scuffing or staining of the wood and adds texture to its appearance.

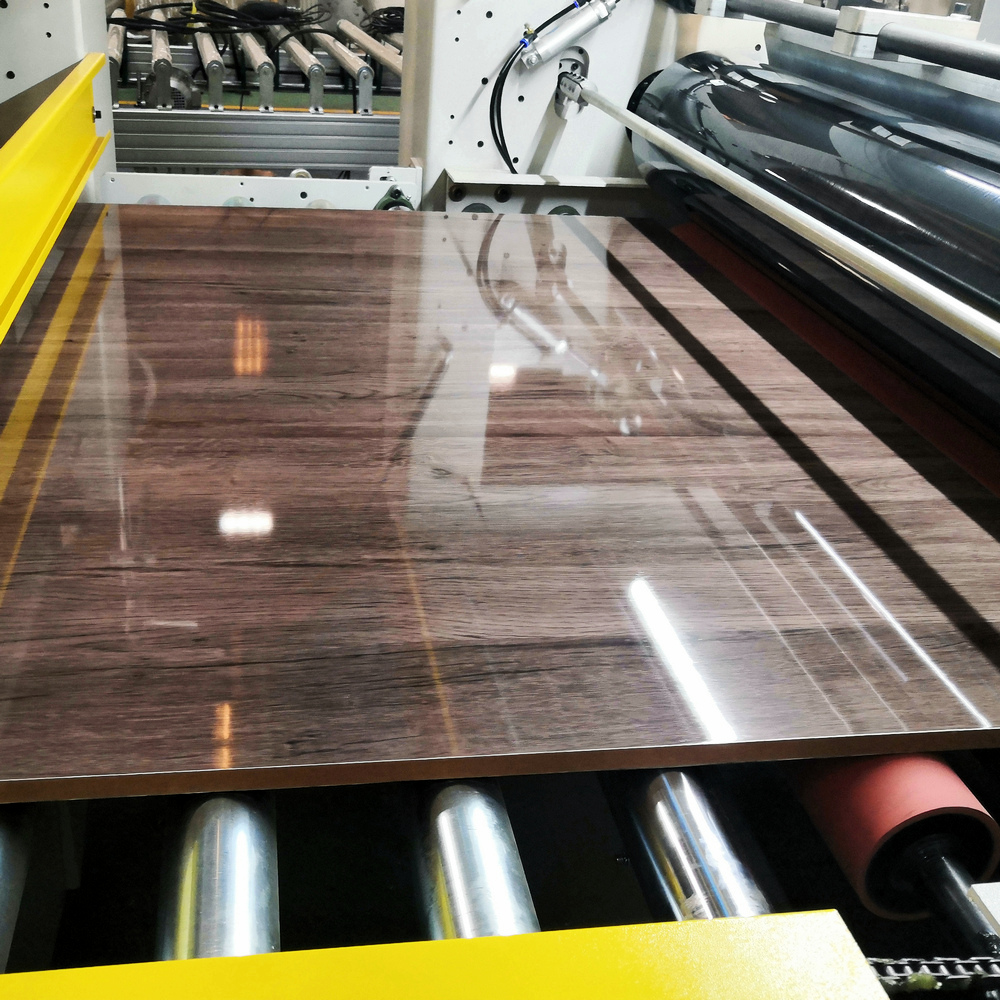

Laminating Materials: Commonly used laminating materials for wood laminators include PVC (polyvinyl chloride) film and PET (polyester) film. These films are durable, waterproof, abrasion-resistant and stain-resistant, providing additional protection and decorative effects.

Laminating effect: Wood laminators can form an even and smooth film on the surface of wood, allowing the grain and color of the wood to be preserved while adding luster and texture. This enhances the appearance of the wood product and makes it more attractive.

OPERATING CONTROLS: Wood laminators typically have adjustable operating parameters such as temperature, pressure and speed to accommodate different types and thicknesses of wood. The operator can adjust the parameters as needed to get the best laminating results.

Automation features: Some advanced wood laminators are equipped with automation features such as automatic feeding, automatic gluing and automatic pressing. These features can increase productivity and reduce manual operations while ensuring consistent laminating quality.

Application Areas:The wood laminating machine is widely used in furniture manufacturing, interior decoration, construction materials and wooden crafts. It can be used to cover timber panels, wooden doors and windows, flooring, cabinets, wall panels and furniture surfaces.

It should be noted that proper film material and suitable operating parameters should be selected when using the wood laminator to ensure the laminating effect and the quality of the wood. In addition, operators should strictly follow the safety operating procedures to ensure a safe working environment.