Why Choose Automated Flat Laminating Machines for Particle Board PET Film Applications?

In the competitive global market for furniture and interior décor, manufacturers are constantly

seeking ways to optimize production efficiency while maintaining impeccable quality. For particle

board applications, laminating PET film offers a durable, aesthetic, and eco-friendly surface solution.

However, traditional laminating processes often struggle with inconsistencies, labor-intensive workflows,

and post-production damage. Enter HESSAN’s Fully Automated Flat Laminating Machine – a game-changer

engineered to address these challenges head-on.

Key Features Driving Global Adoption

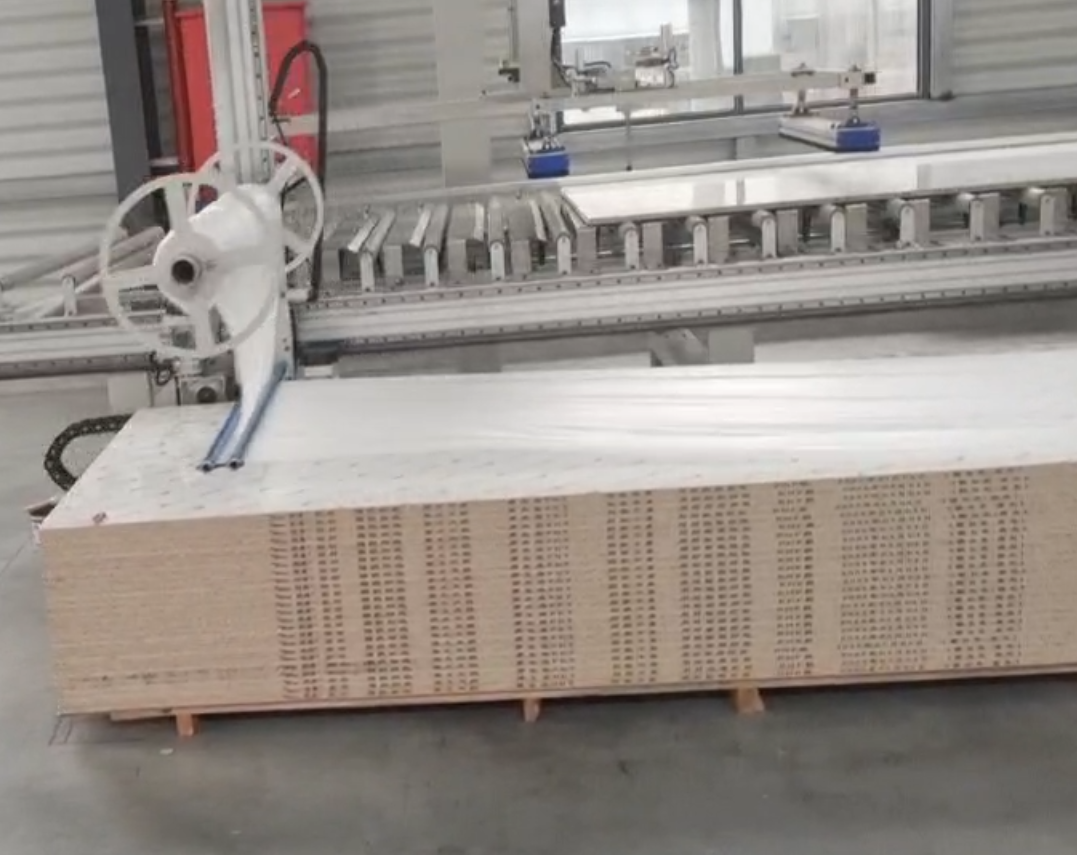

Auto Loading & Unloading Systems

Our laminator Gantry loading machine that handle raw particle boards and finished panels with precision

. This eliminates manual lifting, reduces human error, and accelerates cycle times by 30%. Ideal for

high-volume production lines, the system ensures uninterrupted workflows, even for large-format

boards.

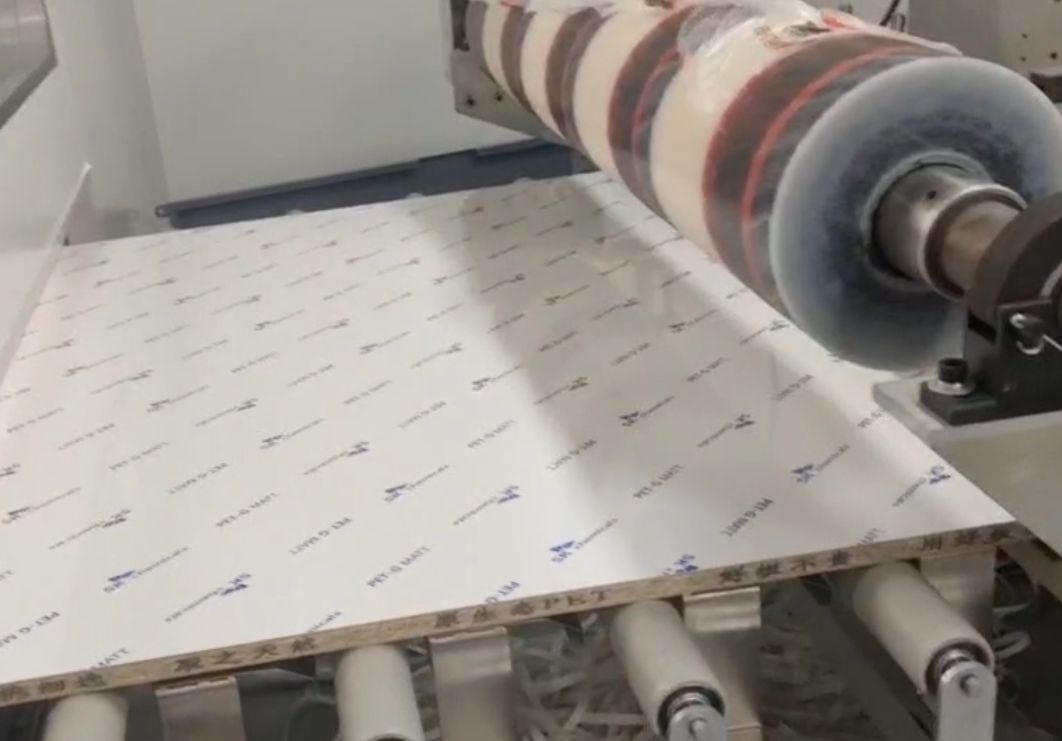

Precision PET Film Application

The machine’s heated roller system ensures bubble-free adhesion of PET film to particle boards, even

on textured surfaces. Advanced temperature and pressure controls guarantee uniform bonding, critical

for high-gloss or matte finishes demanded by global clients.

Built-In Protective Film Application

Scratches during handling or shipping can ruin finished products. HESSAN’s laminator automatically

applies a clear protective film, safeguarding surfaces without slowing down production. This feature is

especially valuable for export-oriented businesses shipping to distant markets.

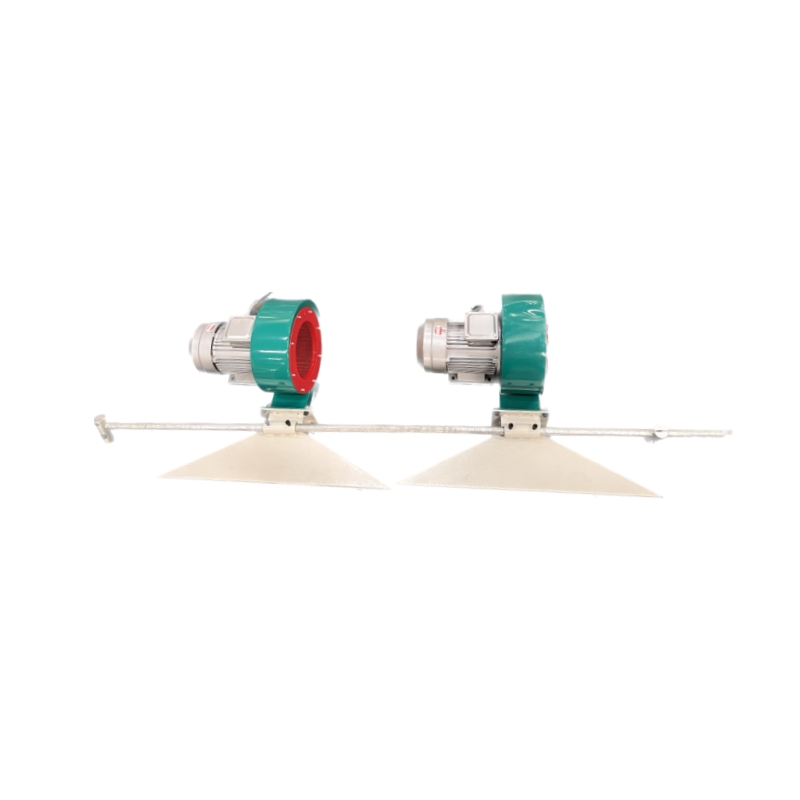

Automatic Pearl Cotton Padding

Post-lamination, the machine seamlessly attaches anti-static pearl cotton padding to the board’s

backside. This not only protects against moisture and impact but also streamlines packaging – a major

advantage for clients prioritizing ready-to-ship solutions.

Why International Manufacturers Trust HESSAN’s Solution

30% Faster ROI: Automation slashes labor costs by up to 40% and boosts output by 60%, ensuring rapid

returns.

Zero Defects: AI-powered sensors detect and correct misalignments in real-time, reducing waste.

Conclusion

For global manufacturers targeting premium markets,HESSAN’s Flat Laminating Machine isn’t just

equipment – it’s a strategic investment. By combining automation, precision, and smart material

handling, we empower businesses to deliver flawless particle board products at unmatched speeds.

Ready to upgrade your production line? Contact our team today for a free consultation!