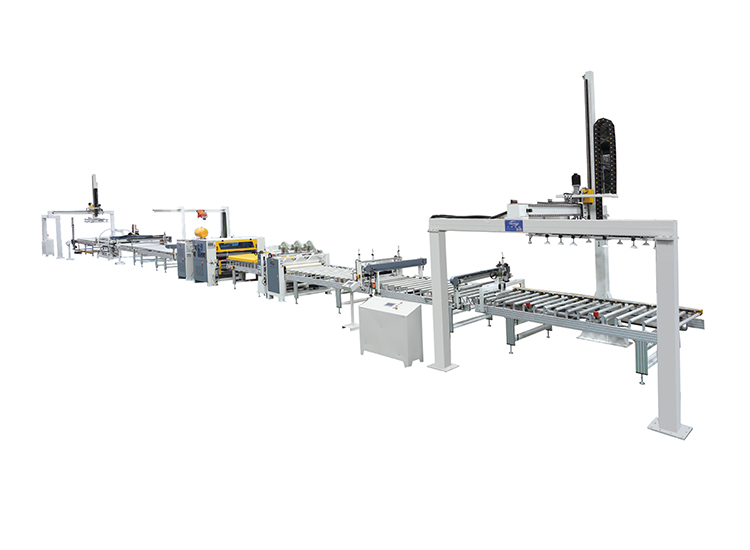

Full automatic PUR HOT Melt glue laminating machine line

HY-PUR-1400D. Full automatic PUR HOT Melt glue laminating machine line. Hessan NEW HOT SALE full automatic PUR laminating machine. This machine is new designed in 2020, and hot sale in China. We have sold 50 more in China during Jan to April 2021. This machine can laminate Not only Transprent PET/PVC, HIGH GLOSSY PVC/PET/PP, but also Acylic sheet, CPL, HPL, Aluminium /steel sheet, Venneer .

Intorduction:

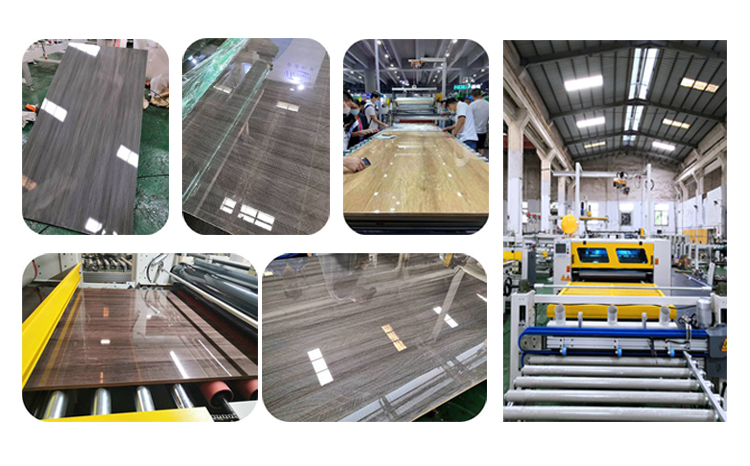

This machine line is using PUR hot melt glue for flat surface lamination with various material, especially for high gloss materials. PUR hot melt glue provide fast chemical reaction with moisture in the air, gives strong adhesion.

Materials:

Core Panel : Chipboard, MDF, Plywood, Gypsum board , Plastic foamed board etc.

Surface Material : PET, PVC, Paper, HPL, CPL, Acrylic, Meter filmetc.

Glue : Suitable with PUR, PO, PSA or EVA based hot melt.

Labour : 2 People for operate this machine

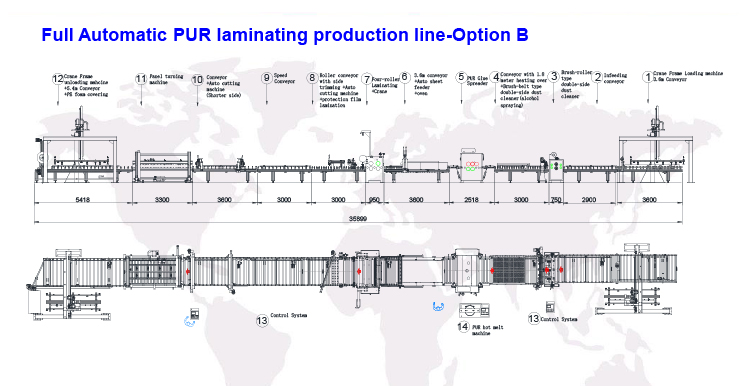

*Working Date*

Panel size:1220mm×2440/2800mm Thickness of panel: 2-40mm

Working speed: 5-17m/min Transmission power: 44.7KW

Heating power: 75.6 KW

Size of machine:36m(L)×4.5m(W)×4.5m(H)

Inverter speed control for the hope line

Minimum Space required: 9m X 45m

Labor required: 2 workers

Capacity: 3-5pcs/min, maximum about 1200pcs/day for 8 hours working

*Machine Funtions*

1. Auto loading machine, saving in labor.

2. In-feeding driving conveyer rollers, Independent power, frequency control.

3. Double side roller brusher machine, for cleaning large particles of dust.

4. In-feeding driving conveyer rollers. With Three belt cleaning unit and IR heating oven.

5. Three roller gluing,single side glue spreading,Oil heating system on dosing roller,applicator roller and smoothing roller. The precise heating elements, which create a stable and uniform、temperature, gives smooth and glossy glue film. Equipped with 200litres glue bulk melt tank, ensure machine run continuously with high output and excellent panel quality.

6. Auto sheet feeding unit, with conveyor and oven.

7. Roller pressing, The pressure is adjustable, with expanding shaft and powder bake, film in rollers can be easily handled.

8. Auto cutting machine with long side trimming unit, Servo motor tracking cut off, saving in labor.

9. Auto short side trmming unit.

10. Auto panel turnover machine.

11. Auto unloading machine, with automatic cover of pearl cotton unit, Prevent board surface from scratching.

*Machine details*

*Product Effects*

*Company Profile*

Hessan Machinery (Guangzhou) Co., Ltd, located in Shawan Town, Panyu District, Guangzhou City, has been dedicated to the research&development&production of board laminating machine and profile wrapping machine. We launched China's first PUR board laminating line in 2007. With nearly 20 years of hard work, "Hessan" brand has won praise and reputation for its first-class quality and first-class service.

At present, the main products of the company include:

1. PUR standard board laminating production line: suitable for laminating PET film, PVC film, PP film, aluminum film, as well as acrylic sheet, fireproof sheet, aluminum sheet, stone plate and other sheets, providing professional solutions according to customer needs.

2. Board/profile wrapping machine: applicable to various boards, indoor/outdoor profiles surface wrapping , ect.

3. White glue laminating production line: suitable for cold white glue laminates with decorative paper and PVC film.

4. Other production lines: acrylic-PVC composite equipment, PET-PVC film composite equipment, honeycomb door laminating line, flooring laminating line.

5. Other supporting equipment: automatic board loading/unloading machine, turnover machine, sanding machine, dust removal machine, pearl cotton laying machine, PVC slitting machine, glue hot melt machine, etc.

*Hessan advantages*

1. With more than 10 years of experience in manufacturing,research and development of PUR board lamination equipment, continuous innovation, Hessan is recognized as the leading brand in China.

2. Insist on treating people with sincerity, we own a large group of customers in domestic and in more than 20 countries and regions around the world, including many large enterprises and listed companies, our product has been widely recognized by the market.

3. With more than 10 years of export experience, the equipment is always produced according one standards for China and intenational customers.

4. We are able to provide seppliers who make boards, PET/PVC or other laminating materials, PUR glue.

5. Two members of after-sales team have more than 10 years of experience in the industry, we offer good service for installation, training, technical guidance,and equipment lifelong after-sales.(Due to the current epidemic situation, it is temporarily impossible to send technicians to other countries)