Materials:

Core Panel : Chipboard, MDF, Plywood, Gypsum board , Plastic foamed board etc.

Surface Material : Transparent PET, Transparent PVC, Paper, HPL, CPL, Acrylic, Meter filmetc.

Glue : Suitable with PUR, PO, PSA or EVA based hot melt.

Labour : 5-6 People for operate this machine

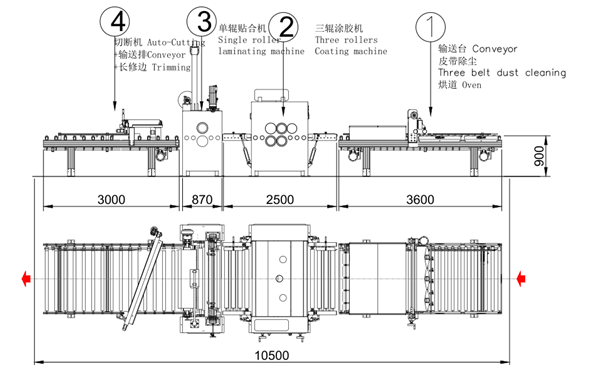

1.1.Working table with conveyor rollers.

1.2.Dust cleaning is for removing the dust and small articles on the plywood board before coating the glue.

1.3.Panel preheating oven before gluing. Because of the PUR hot melt, the preheating system can prolong the working time of adhesive.

2.Single side glue spreading,. Oil heating system is used on dosing roller, coating roller and crush roller. The precise heating elements, which create a stable and even temperature, make the glue coating flat, equal and glossy. Combining with the glue melt tank, this machine can continuously provide top quality and high efficient production.

3.Roll Presser. Single roller with hydraulic syetem gives the pressure to the combined materials. The pressure is adjustable, with expanding shaft and powder bake, film in rollers can be easily handled.

4. Working talbe for with conveyor rollers ,and equip with Auto-cutting machine and trimming.